How long is the service life of brushless motors

In brushless motors, commutation is achieved through the control circuit in the controller (usually a Hall effect sensor+controller, but a more advanced technology is a magnetic encoder). Brushless motors use electronic commutation, with the coil stationary and the magnetic poles rotating. Brushless motors use a set of electronic devices that utilize Houle components to sense the position of permanent magnets. According to this understanding, electronic circuits are used to switch the direction of current in the coil in a timely manner to ensure that magnetic force is generated in the correct direction to drive the motor, eliminating the drawbacks of brush motors. Brushless motor is a new type of motor, which has the characteristics of high efficiency, energy saving, and silence because it does not have rectifiers and carbon brushes.

The service life of brushless motors is around 15000 to 20000 hours,(our

B1234 BLDC motor can be 10000 hours) but the specific service life still depends on factors such as the motor's material, industry, application field, and working mode.

Firstly, three aspects are related to the factors of the brushless motor itself:

1. Bearing life (if the bearing is damaged, it needs to be replaced)

2. Steel demagnetization (this is a last resort unless you can magnetize)

3 coil problems (usually aging time exceeds 10 years, how to avoid coil aging? This requires that the temperature of the coil should not be too high and ensure good heat dissipation, thereby extending its service life. Of course, overheating and combustion also belong to this category. Obviously, bearings and coils are crucial to the lifespan of brushless motors. Do not think that small motors occupy a small and inconspicuous position in the equipment. If the quality of the motor you purchased is poor, and the parts used for low-end brand motors (such as bearings and coils) are of poor quality, the equipment will need to replace the motor. If there are any problems, the motor should replace the bearing coils. It's troublesome to remember.

The second environmental factor for use: The service life of brushless motors will be affected by factors such as temperature, humidity, dust, and corrosion in the operating environment. If used in harsh environments, the service life of brushless motors will be shortened.

Load factor: The load of a brushless motor also affects its service life. If the load is too large or the operating time is too long, it will cause damage to the brushless motor, thereby affecting its service life. The power quality of brushless motors can also affect their service life, as inappropriate electrical parameters such as power voltage and waveform can affect their service life.

III Maintenance factors: Brushless motors require regular maintenance, such as cleaning, lubrication, and tightening screws. Improper maintenance can also affect the service life. Due to the different technical levels of brushless motor operators, unexpected errors may occur when operating the motor, such as immediate shutdown after starting. Overload start; Failure to start will cause damage to the brushless motor, thereby affecting its service life. Although brushless motors have many advantages that attract users, Bian Xiao strongly recommends that if users are unaware of brushless motors, they should use familiar motors or use them under the guidance of the motor manufacturer.

3、 Methods to extend the service life of brushless motors

1. Reasonable selection: Select the appropriate specifications of the motor according to the usage requirements, so that it operates within the rated load range.

2. Maintain good ventilation: Brushless motors require good ventilation to maintain normal operating temperature and extend their service life.

3. Regular inspection and maintenance: Regularly inspect, clean, lubricate, tighten and maintain the brushless motor to extend its service life.

4. Reasonable load distribution: For long-term use, the load of the motor should be reasonably distributed to avoid excessive load in a short period of time.

5. Quality assurance: Choosing high-quality brushless motors from reputable manufacturers and selecting high-quality materials is an important guarantee for ensuring the service life of brushless motors.

【 Conclusion 】 The service life of brushless motors can be extended through various methods, but the specific service life still depends on factors such as industry, application field, and working mode. In practical applications, we need to choose suitable brushless motors according to the situation, carry out reasonable maintenance and upkeep, in order to extend their service life and improve production efficiency.

Previous:

None

Previous:

None  Next:

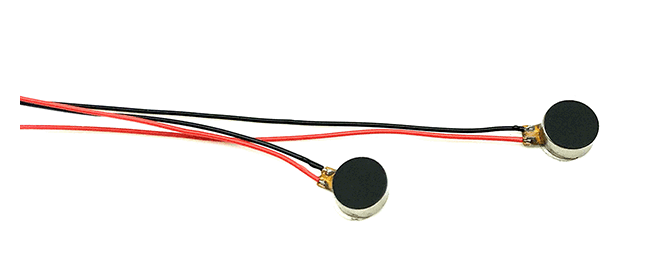

Lifetime for phone motor

Next:

Lifetime for phone motor