Tel. : +86 577 6231 0509 E-mail : info@vibrationmotor.net

Mobile vibration motor Introduction

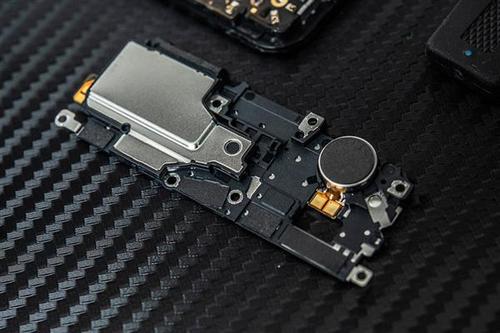

Mobile phone vibration motor is a kind of DC brush motor, which is used to realize the vibration function of mobile phone.

When receiving SMS or phone, the motor starts, driving the eccentric wheel to rotate at high speed, so as to generate vibration.

Nowadays, the volume of mobile phone vibration motor is smaller and smaller, so as to meet the needs of the lighter and thinner mobile phone body.

Catalog action principle

Causes of mobile phone vibration

Matters needing attention

China production scale

Action principle

The outer part of the motor is made of engineering plastics. In addition to the outer box, there is a small DC motor to drive the eccentric wheel. In addition, there is a very simple integrated circuit to control the start and stop of the motor. When the mobile phone is set to "vibration" state, the control circuit is connected. There is an eccentric wheel on the motor shaft. When the motor is rotating, the center mass of the eccentric wheel is not on the motor's center of rotation, which makes the motor in a state of continuous imbalance, resulting in vibration due to inertia.

Causes of mobile phone vibration

(1) It is caused by the eccentric rotation of the metal bar.

Due to the high speed rotation of the metal bar in the sealed metal box, the internal air of the metal box also makes violent movement through friction. This will cause the vibration of the whole sealed metal box, and then drive the whole mobile phone to generate vibration. It can be seen from the above calculation that the high-speed rotation energy of the metal bar accounts for a large proportion, so this is the main reason for the vibration of the mobile phone.

(2) Caused by unstable center of gravity.

Since the metal bar connected to the rotating shaft of the vibration motor is not arranged in the way of geometric symmetry, the rotating shaft of the vibration motor will turn a deflection angle in the direction of the center of mass. Therefore, the metal bar does not actually rotate in the horizontal plane. In the rotation, the position of the center of mass will change with the change of the position of the metal bar, so the rotation plane of the metal bar also changes with the horizontal plane at a certain angle. This kind of motion of the center of mass in a certain space will cause the position of the object to move. When the change is small and very frequent, that is to say, it is vibration on the macro level.

Matters needing attention

1. When the motor works at its nominal rated voltage, its comprehensive performance is excellent. It is suggested that the working voltage should be close to the rated voltage when the mobile phone circuit is designed.

2. The output impedance of the control module supplying power to the motor should be kept as small as possible to prevent the output voltage from dropping significantly and affecting the vibration sense.

3. When checking or testing the locked rotor current of the column motor, the locked rotor time should not be too long (less than 5 seconds is appropriate), because all the input power is converted into heat energy (P = I2R) during the locked rotor, too long time may lead to high temperature rise of the coil and deformation, affecting the performance..

4. When designing the positioning card slot of the motor with mounting bracket, the gap between the motor and the mobile phone shell should not be too large, otherwise additional vibration (mechanical noise) may be generated. The rubber sleeve fixation can effectively avoid mechanical noise, but attention should be paid to the interference fit between the positioning slot on the shell and the rubber sleeve, otherwise the vibration output of the motor will be affected and the vibration sense will be reduced.

5. Avoid being close to the strong magnetic area during transfer or use, otherwise it may cause the surface magnetic distortion of motor magnetic steel and affect the performance.

6. Pay attention to the welding temperature and time during welding. It is recommended to use 320 ℃ for 1-2 seconds. If the time is too long and the temperature is too high, the insulation skin of the lead wire may be damaged.

7. Take out the motor unit from the packing box or avoid pulling the lead wire forcibly during the welding process, and do not bend the lead wire at a large angle for many times, otherwise it may damage the lead wire.

Domestic production scale

With more and more people owning mobile phones, the number of domestic enterprises producing mobile phone motors is also increasing significantly, but they are mainly distributed in a few provinces and cities, with the largest distribution in Guangdong, followed by Zhejiang, Tianjin, Shanghai and other places, mainly dominated by Japanese and Korean enterprises, with the total output accounting for 80% of the world, of which the export volume accounts for the majority. At present, the annual output value of domestic mobile phone motors It is 30 billion yuan, and the market demand of domestic mobile phones for motors is about 10 billion yuan. According to the market environment and development situation in recent years, the global market demand for mobile motors will maintain a steady growth. From 2005 to 2007, the average annual growth rate of mobile Motors has reached 15%

# phone vibration motor #small DC motor #brush dc motor#mini motor#iphone motor